In Casting a Mold Is Used Into Which __________

Pressure casting methods use forces other than gravity to control the flow of metal into a permanent mold. Air or gas vacuums mechanical or centrifugal forces are all used in pressure casting.

Shape Casting An Overview Sciencedirect Topics

It is also used to produce long hollow objects without resorting to coresfor example to cast pipe.

. - Made of metal or ceramic refractory material. Traditional metal casting techniques include lost-wax casting plaster mold casting die casting and sand. Here the long cylindrical mold is horizontal and is spun about the axis of the cylinder as metal is poured into the mold.

See also how far is florida from the equator. Two categories of casting process. The resulting cast will be an exact likeness of the shape of the hollow mold form.

Metal casting is a 7000-year-old process used in both manufacturing and fine art. Mold on the other hand is the hollow cavity that has been formed in order to imprint the object and take a replica out of it. If cores made of sand or plaster used in the PMC method is called as semi-PMC 68.

It is used to produce small and medium-sized parts that require high dimensional accuracy. Resulting mold has a stable shape and is both chemically and thermally resistant. Permanent mold processes uses a permanent mold which can be used over and over to produce many castings.

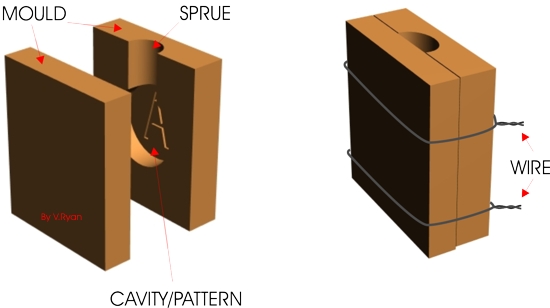

Which three metals commonly cast in permanent mold casting. Casting is a technique used in sculpture in which a mold is created of the desired sculpture and then molten material is poured into the mold to create an exact replica of the original. The process of making a cast is known as a casting while the.

If you dont have the release agent simply soak the mold into some hot water which can effectively soften up the mold and resin. This can be done with a variety of materials but most commonly bronze or. During metal casting molten metal is transferred from a crucible into a mold to create a positive metal cast object.

These methods allow foundries to precisely control the rate at which a mold fills. Cast is the final product that is obtained when the casting liquid is poured into the mold and is left to harden. Consequently surfaces have to be designed in the direction of mold opening.

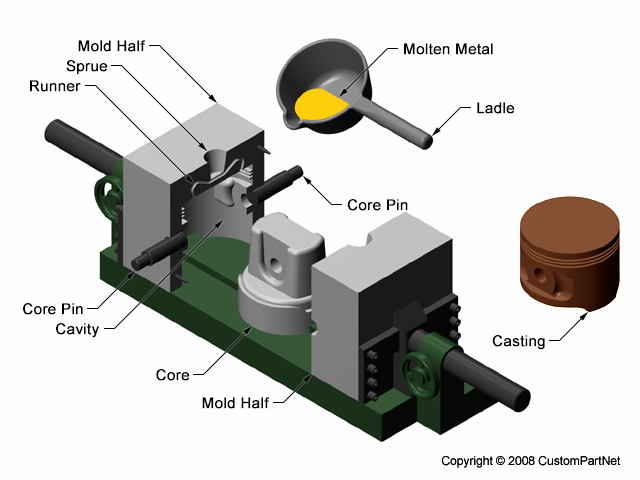

These metal casting processes may be completed in a. This mold material is suitable both for small detailed casts and large objects ie statues. Permanent mold casting PMC is the process of transferring molten metal to a metal mold by the gravity assistance and ensuring that the metal solidifies in this mold.

Select the resin casting molds that can tolerate wear pressure and damage. There are several types of molds that are used in the casting process. During metal casting molten metal is transferred from a crucible into a mold to create a positive metal cast object.

Others are permanent and are reused again and again. The process include molds made from iron and steel. The solidified part is also known as the casting which is ejected or broken from the mold to complete the process.

- Ex sand plaster. Traditional metal casting techniques include lost-wax casting plaster mold casting die casting and sand casting to name a few. The liquid materials used for vacuum casting are elastomers such as plastic and rubber.

The parting line divides the die casting mold into two allowing easy mold opening and ejection of casting. Casting is pouring molten liquid into a mold where it is subsequently allowed to cool solidify before ejection for use. The metal mold which is the same shape as the finished product is reused to produce many.

The metal and mold are cooled and the metal object is removed and finished. A resin mold typically made from flexible rubbers allows both natural and synthetic resins to be cast into pre-determined shapes. The metal and mold are cooled and the metal object is removed and finished.

Casting is a manufacturing process in which a liquid material is usually poured into a mold that contains a cavity of the desired shape and then allowed to solidify. You can use it to cast many materials including polyurethane epoxide polyester plaster concrete cement wax low melting alloys or soap. Casting is a process in which a liquid is poured into a mold in order to produce a product.

Gravity always works with the same force but man-made forces can. True or False Steel can be cast in permanentmold processes but because of its high melting temperatures the mold must be made of a refractory material. Vacuum Casting is a casting process in which a liquid material is drawn into a silicone mold using a vacuum to create complex components.

The utility model discloses a kind of metallicity gravity casting die for being used to make crankcase including rear mould framing plate and brute spring after described rear mold pillar is provided with above mould framing plate rear mould bases is provided with above the rear mold pillar the side of mould bases is provided with guide hole set after described preceding mould. Do not use sharp tools to peel them out in case the mold gets ruined. It is used for the casting of small precious-metal objects so that essentially all of the metal goes into the casting instead of the gates and risers.

The molds can range from very cheap sand molds to elaborately machined chromium-steel molds costing well into the 6 figure range. Main Differences Between Cast and Mold. Casting is used for producing parts to near-net ie.

Sometimes we use permanent mold casting to replace high-pressure die casting and sand casting. The easiest example of what a mold is that almost everyone has used before is an ice cube tray. The manner a resin casting molds is designed and built as well as the material used determine its durability.

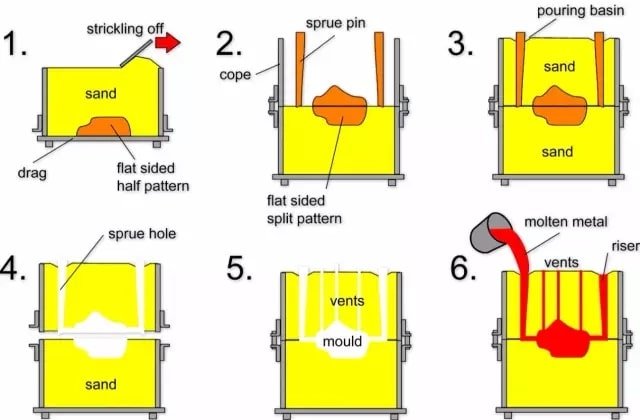

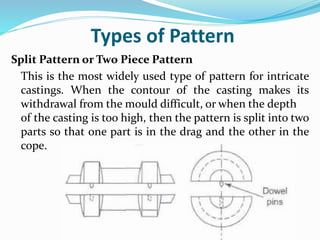

Casting from long and skinny molds can be hard to get out try to use the mold release agent like detergent cooking oil and etc. Furthermore the surface of parts depends on their position from parting lines. Expendable mold processes uses an expendable mold which must be destroyed to remove casting.

Some are temporary and are destroyed during the casting process. Likewise high pressure die casting permanent mold casting uses a reusable steel mold instead of a one-time use sand mold and sand cores can be used to create internal voids and undercuts. Molds are negative forms that are used to shape casting materials creating duplicates of the model object the mold was made from.

Vacuum casting is sometimes referred to as polyurethane casting or urethane casting as polyurethane resin a type of. Also make sure it has a streamlined style that fits everywhere. A busy mom or a construction worker will appreciate this products durability.

Resin molds can be used to create plastic-like parts for use in manufacturing or for lightweight jewelry components. Shell mold casting is a one-time mold casting process that uses coated sand to form a model. The molten metal is poured into disposable shells which are usually thin-walled shells.

What Is Sand Casting And How Does It Work Metaltek

Solved Which One Of The Following Casting Processes Produces The Pr

10 Different Types Of Casting Process Machinemfg

Solved Which One Of The Following Casting Processes Produces The Pr

Permanent Mold Casting An Overview Sciencedirect Topics

Pattern Functions Casting Questions And Answers Sanfoundry

Sand Casting An Overview Sciencedirect Topics

Permanent Mold Casting An Overview Sciencedirect Topics

Mcq On Injection Mould Pdf Polymers Plastic

Solved The Casting Produced By Forcing Molten Metal Under Pressure

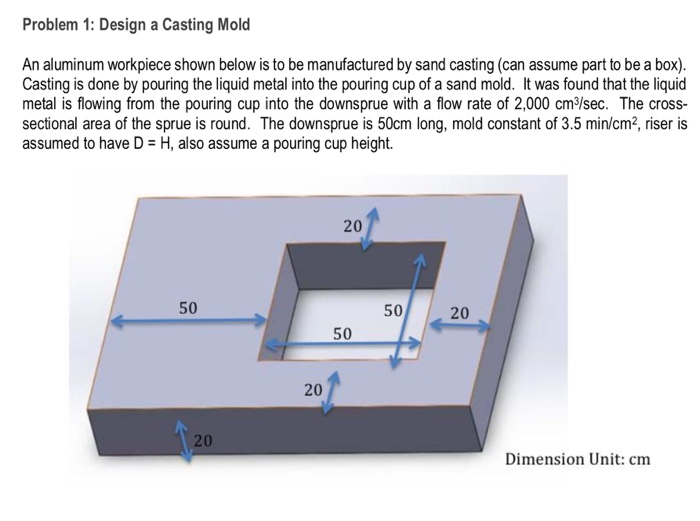

Solved Problem 1 Design A Casting Mold An Aluminum Chegg Com

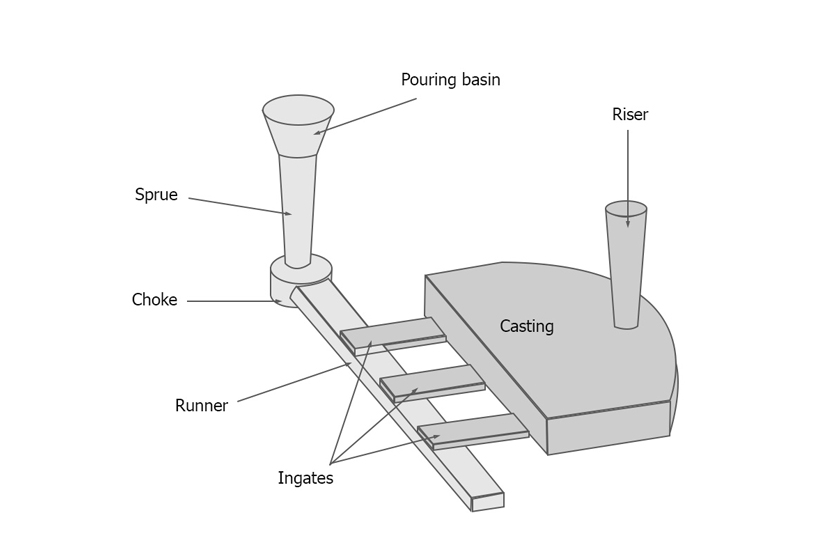

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Comments

Post a Comment